Film Faced Plywood

ROCPLEX Film Faced Plywood is engineered to meet the rigorous demands of the construction industry. This high-quality plywood features a phenolic film overlay that provides a smooth, durable surface, making it ideal for concrete formwork. The phenolic film enhances the plywood resistance to moisture, abrasion, and chemicals, ensuring it can withstand harsh construction environments.

The core of ROCPLEX Film Faced Plywood is constructed from premium hardwood veneers, which are cross-laminated and bonded with strong adhesives. This construction method ensures the plywood’s superior strength and stability, allowing it to support heavy loads and maintain its integrity over multiple uses.

One of the standout features of ROCPLEX Film Faced Plywood is its excellent reusability. The durable film coating and robust core structure enable the plywood to be reused multiple times without compromising its performance. This makes it a cost-effective solution for large-scale construction projects where longevity and reliability are paramount.

In addition to its functional benefits, ROCPLEX Film Faced Plywood is also environmentally friendly. The plywood is made from sustainably sourced wood, and the manufacturing process adheres to strict environmental standards, ensuring a minimal ecological footprint.

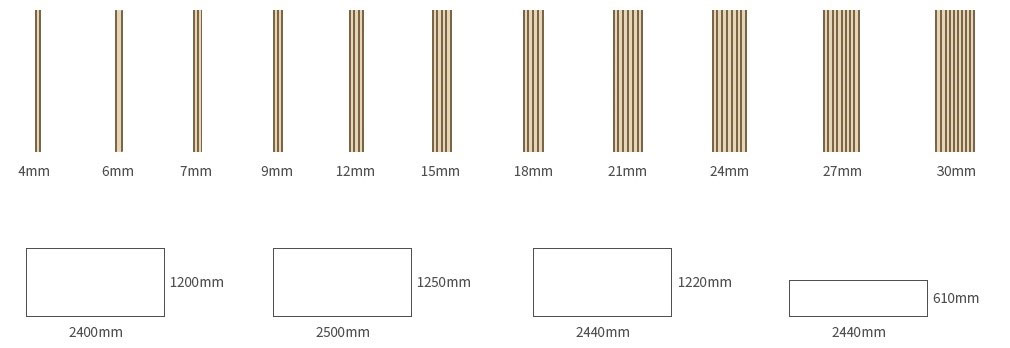

ROCPLEX Film Faced Plywood is available in various sizes and thicknesses to meet the diverse needs of construction projects. Whether you’re building formwork for concrete walls, columns, or slabs, this plywood provides a reliable and efficient solution that delivers consistent results every time.

|

|

|

| Black Film Faced Plywood | Brown Film Faced Plywood | Yellow Film Faced Plywood |

| Thickness (mm) | Length (mm) | Width (mm) | Type | Grade |

| 4 | 2440 | 1220 | Birch / Hardwood | AA |

| 7 | 2440 | 1220 | Birch / Hardwood | AA |

| 9 | 2440 | 1220 | Birch / Hardwood | AA |

| 12 | 2440 | 1220 | Birch / Hardwood | AA |

| 15 | 2440 | 1220 | Birch / Hardwood | AA |

| 17 | 2440 | 1220 | Birch / Hardwood | AA |

| 18 | 2440 | 1220 | Birch / Hardwood | AA |

| 19 | 2440 | 1220 | Birch / Hardwood | AA |

| 25 | 2440 | 1220 | Birch / Hardwood | AA |

| 28 | 2440 | 1220 | Birch / Hardwood | AA |

■ Smooth Surface: The phenolic film overlay provides a smooth and even surface, ensuring high-quality concrete finishes.

■ High Durability: Made from premium hardwood veneers, ROCPLEX Film Faced Plywood is designed to withstand heavy loads and harsh conditions.

■ Moisture Resistant: The phenolic film coating offers excellent resistance to moisture, preventing warping and swelling in wet environments.

■ Abrasion and Chemical Resistance: The plywood’s surface is highly resistant to abrasion and chemicals, ensuring long-lasting performance.

■ Reusability: ROCPLEX Film Face Plywood can be reused multiple times, making it a cost-effective solution for construction projects.

■ Environmentally Friendly: Manufactured from sustainably sourced wood, this plywood is environmentally friendly and adheres to strict ecological standards.

■ Versatile Sizes: Available in various sizes and thicknesses, it meets the diverse needs of different construction projects.

■ Strong Core: The cross-laminated hardwood veneer core provides superior strength and stability, ensuring reliable performance.

■ Easy to Handle: Lightweight and easy to cut, ROCPLEX Film Faced Plywood is convenient to handle and install on-site.

ROCPLEX Anti Slip Plywood FAQ

Q: What is film-faced plywood?

A: Film-faced plywood is a type of plywood that is coated with a thin layer of phenolic or melamine film on both sides. This coating provides a smooth, durable surface that is resistant to moisture, abrasion, and chemicals. It is commonly used in construction for concrete formwork, shuttering, and other applications where a strong, smooth surface is required.

Q: What are the benefits of film faced plywood?

A: Film-faced plywood offers several benefits, including high durability, moisture resistance, and a smooth surface that ensures high-quality concrete finishes. It is also resistant to abrasion and chemicals, making it suitable for harsh environments. Additionally, it can be reused multiple times, providing a cost-effective solution for construction projects.

Q: Is film faced plywood waterproof?

A: Yes, film-faced plywood is designed to be highly resistant to moisture. The phenolic or melamine film coating provides a waterproof barrier, preventing the plywood from absorbing water and maintaining its structural integrity even in wet conditions. This makes it ideal for outdoor and concrete formwork applications.

Q: How thick is film faced plywood?

A: Film-faced plywood comes in various thicknesses to suit different construction needs. Common thicknesses range from 12mm to 25mm, with 18mm being a popular choice for many applications. The thickness you choose will depend on the specific requirements of your project.

Q: Which is better, MDF or MDO?

A: Medium Density Fiberboard (MDF) and Medium Density Overlay (MDO) serve different purposes. MDF is made from wood fibers bonded with resin and is typically used for interior applications such as furniture and cabinetry due to its smooth finish and ease of machining. MDO, on the other hand, is plywood with a weather-resistant resin overlay, making it more suitable for exterior applications and signage. If you need a material for outdoor or high-moisture environments, MDO is generally the better choice due to its enhanced durability and resistance to the elements.