Xlife Formwork Plywood

ROCPLEX ® Xlife Formwork Plywood is a premium product, designed to meet the rigorous demands of modern construction projects. This high-grade plastic/wood composite sheet is coated with a durable plastic layer, significantly extending its lifespan and ensuring uniform concrete faces over many uses. The edges are meticulously sealed with three layers of waterproof paint to prevent moisture penetration, ensuring long-term performance and reliability.

The plywood is certified to AS 6669 standards, ensuring it meets stringent quality and safety benchmarks. With a stress grade of F22, Xlife Formwork Plywood performs exceptionally well in both parallel and perpendicular directions to the grain. The sheets are constructed with high-grade birch veneers bonded together with a Super E0 waterproof adhesive, providing superior bond strength and stability.

ROCPLEX Xlife plywood features a non-absorbent surface, preventing swelling and shrinkage. This guarantees a first-class concrete finish even after multiple uses. When handled correctly and used under optimal conditions, these plywood sheets can achieve up to 350 use cycles, making them a cost-effective and reliable choice for builders.

The plywood robust, smooth surface allows for easy cleaning and optimal nailability, ensuring it remains in top condition throughout its usage. Additionally, the environmentally friendly PEFC certification highlights ROCPLEX commitment to sustainable manufacturing practices.

|

|

| Green Plastic Plywood | Blue Plastic Plywood |

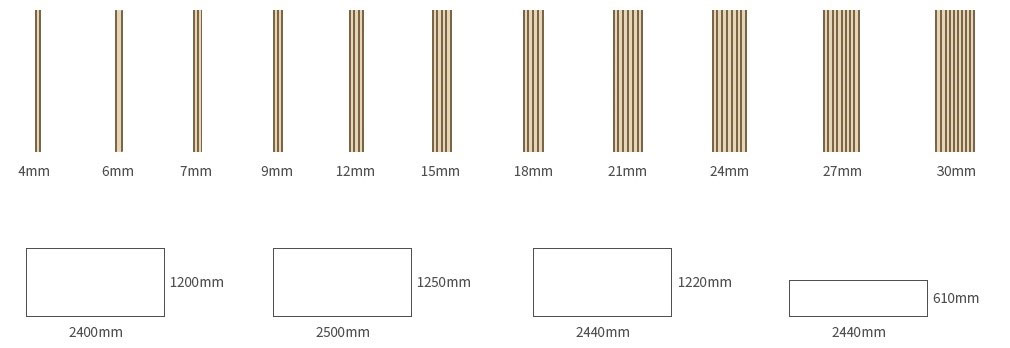

| Thickness (mm) | Length (mm) | Width (mm) | Type | Grade |

| 4 | 2440 | 1220 | Birch / Hardwood | AA |

| 7 | 2440 | 1220 | Birch / Hardwood | AA |

| 9 | 2440 | 1220 | Birch / Hardwood | AA |

| 12 | 2440 | 1220 | Birch / Hardwood | AA |

| 15 | 2440 | 1220 | Birch / Hardwood | AA |

| 17 | 2440 | 1220 | Birch / Hardwood | AA |

| 18 | 2440 | 1220 | Birch / Hardwood | AA |

| 19 | 2440 | 1220 | Birch / Hardwood | AA |

| 25 | 2440 | 1220 | Birch / Hardwood | AA |

| 28 | 2440 | 1220 | Birch / Hardwood | AA |

■ High Durability: Xlife Formwork Plywood features a robust plastic/wood composite with a hard-wearing plastic coating, significantly extending its lifespan.

■ Waterproof: Edges are sealed with three layers of waterproof paint, preventing moisture penetration and ensuring longevity.

■ Certified Quality: Independently certified to AS 6669 standards, guaranteeing high quality and safety.

■ Superior Strength: Stress grade F22, providing excellent performance in both parallel and perpendicular directions to the grain.

■ Environmental Sustainability: PEFC certified, demonstrating a commitment to sustainable manufacturing practices.

■ Non-Absorbent Surface: Prevents swelling and shrinkage, ensuring a smooth, premium concrete finish even after multiple uses.

■ Multiple Use Cycles: Capable of up to 350 use cycles under optimal conditions, offering exceptional value for money.

■ Easy Handling: Smooth surface allows for easy cleaning and optimal nailability, maintaining top condition throughout its usage.

■ High-Grade Construction: Made from high-grade birch veneers bonded with Super E0 waterproof adhesive, providing superior bond strength and stability.

ROCPLEX Xlife Formwork Plywood FAQ

Q: What is Xlife Formwork Plywood?

A: Xlife Formwork Plywood is a high-quality construction material designed by ROCPLEX. It is a high-grade plastic/wood composite sheet with a durable plastic coating, offering a long lifespan and consistent concrete faces over multiple uses.

Q: What are the main benefits of using Xlife Formwork Plywood?

A: The main benefits of using Xlife Formwork Plywood include its high durability, waterproof edges, and superior strength (F22 stress grade). It provides a smooth, premium concrete finish even after many uses, is environmentally certified (PEFC), and can be used up to 350 cycles under optimal conditions. Its robust construction and easy handling make it ideal for various construction applications.

Q: How should I maintain Xlife Formwork Plywood for the best results?

A: To maintain Xlife Formwork Plywood, follow these steps:

Protect the panels from water and direct sunlight.

Store on leveled ground to avoid deflection.

Seal edges and holes after cutting or drilling with appropriate sealant.

Clean panels immediately after use with plastic or nylon tools.

Oil the panels before each use with a high-quality, biodegradable release agent.

Proper maintenance will extend the lifespan and usability of the plywood.

Q: What applications are suitable for Xlife Formwork Plywood?

A: Xlife Formwork Plywood is suitable for various construction applications, including wall formwork systems, frame formwork, and custom formwork designs. Its durable and smooth surface ensures a premium concrete finish, making it ideal for high-visibility projects. Additionally, it is suitable for both commercial and residential projects, providing versatile solutions for different construction needs.

Q: How does Xlife Formwork Plywood compare to traditional plywood?

A: Compared to traditional plywood, Xlife Formwork Plywood offers significantly higher durability and a longer lifespan due to its high-grade plastic coating and waterproof edges. It provides superior strength (F22 stress grade) and a smooth, premium concrete finish even after multiple uses. Additionally, it is environmentally certified and can be reused up to 350 cycles under optimal conditions, making it a cost-effective and reliable choice for construction professionals.